|

Qingdao Senwang steel structure building stock Co.,Ltd

|

Construction Design Steel Structure Warehouse suppliers Steel Structure Warehouse factory

| Price: | 600.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Light weight: Save cost

2. Easy installation

3. Safety: Fire-proof materials

4. Good sound insulation

5. Meet specials designs due to it is eas

Construction Design Steel Structure Warehouse suppliers Steel Structure Warehouse factory

Technical Parameters

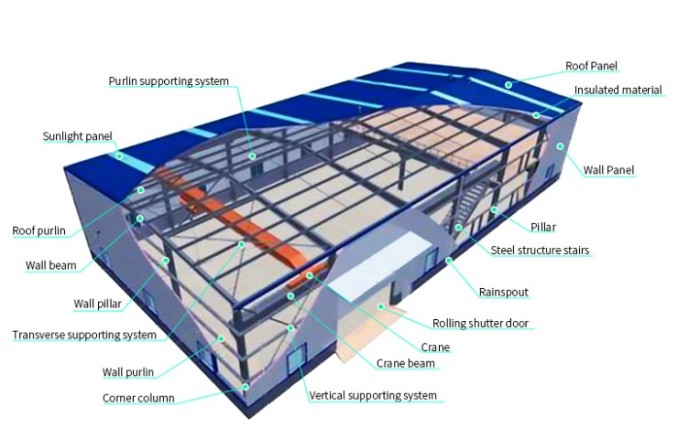

Item Name | Steel Structural Buildings - Steel workshop / warehouse |

Main Steel | Main steel structure--Q345/Q235, etc. |

Wide span | Single span or multiple spans, the max span clear distance that we had done is 90m(without middle column). |

Surface | Painted or Hot Dip Galvanized |

Connection method | welding connection or bolt connection |

Column and Beam | Welded H section, Hot Rolled Section Steel, grid column, pipe&tube column. |

Purlin | C-section or Z-section |

Roof & Wall Panel | EPS/Rock wool/PU Sandwich panel; Single Steel Sheet (prepainted,Galvanized,Galvalume,etc.); Fiber glass wool; Fireproof paper; Transparent panel (light panel); Trim; Screw, Rivet, Glass glue, etc. |

Window | Plastic steel, Aluminum alloy, etc. |

Door | Sliding door, Rolling up door, Industrial Lifting door, etc. |

Other Accessories | Down pipe, Floor decking panel, Out gutter, Ventilator, Bolts, etc. |

Service | Design, Detailing, Fabrication and Installation |

Making quotation according to customer's drawing or as per customer's dimension and requirement; | |

Packing | We possess the unique most professional and best packaging in China presently - FRAMING PACKAGE, which perfectly protects the structural steel members from any impact damage during the transport. |

Load into 40/20GP, 40HQ, 40OT or Bulk carrier |

Brief Introduction:

Light steel structure garage is a new type of building structure system,which is formed by the main steel framework linking up H section,Z section,C section or U section steel components,roof and walls using a variety of panels and other components such windows,doors,cranes,etc.Light steel structure building is widely used as warehouses,workshops,large factories...etc.

Characteristics

1.Wide span: single span or multiple spans, the max span is 36m without middle column.

2.Low cost: unit price range from USD 30/m2 to USD 60/m2 according to customers request.

3.Fast construction and easy installation.

4. Long using lifespan: up to 50 years.

5.Others: environmental protection, stable structure, earthquake resistance, water proofing, and energy conserving.

Detailed Images

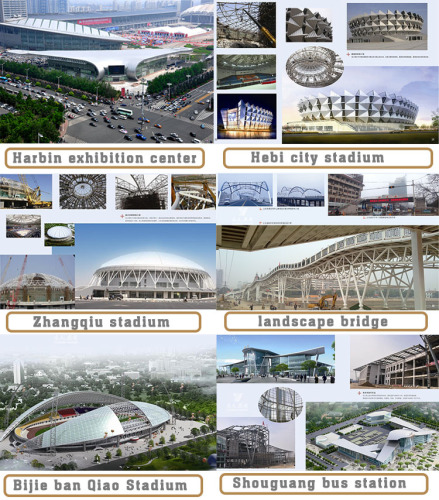

Advantages

1. We have a group of professional engineers, most of whom has more than 10 years' experiences in architecture field.

2. Established for more than ten years, our company has got a various of experiences in design, manufacture, installation and so on. The work staffs have excellent skills. Some of them had helped customers to install the warehouse around the world.

3. We also have possessed more than 80 sets of large precise and domestically advanced processing equipments, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, slitters, shot blasting machines and so on.

4. Besides manufacture according to customers' requirements, we also established a set of production standards. With perfect technique, excellent quality, reasonable price, top-grade services, we have won the favor of lots of customers at home and abroad.

5. "Moral personality decides product quality." is our guarantee to the products. "Customers come first." is our everlasting pursuit. Believe your choice; we'll give you a satisfied answer.

Company Information

we are big group factory and have more than 25 years experience of steel structure warehouse project The first design&Engineering Service,Excellent product and perfect has won the praise of customers and want to cooperate with more and more friends and customer add our team .

why choose us

Packaging & Shipping

Our service

1. Professional design and engineering team

Full solution for house design. We could make the design for whole house as per your requirement.

2. Procurement and Manufacture for all material for prefabricated building

We have a professional procurement team to make sure all the materials are with good quality. And our factory operation under ISO standard, to make sure the fabrication works with high technology.

3. Site management & Installation supervision

We could send our engineers to help for the installation supervision, you just need to prepare a team which know normal construction works will be OK.

FAQ

Q1: What are your main products?

A: Our man products have prefab K house, T house, SHS house, H house, container house, light steel structure villa, steel structure warehouse, sentry box, sandwich panel and other constructive materials.

Q2: What will client provide before factory offers good quotation?

A: When we receive inquiry from client, client please fills purchasing intention sheet, providing us with information of house dimensions, draft drawing, layout and materials for prefabricated house. We will design the drawings and offer competitive quotation with the above information.

Q3: What are main materials of prefabricated house?

A: Our prefabricated house materials mainly include light steel structure, sandwich panel, roof tile, door, window, covers, screws and other accessories.

Q4: How you calculate the total area?

A: Industry calculation rule as below:

(1) house area = exterior house length X exterior house width X floor

(2) canopy area=exterior house length X 1/2 X canopy width

(3) staircase area = 4.5 sqm X quantity of staircase

(4) corridor area = exterior house length X corridor width

(5) total area = (1) + (2) + (3) + (4) + (5)

Q5: What drawing of house will factory supply?

A: Plan drawing, elevation drawing, sectional drawing, foundation drawing, installation drawing.

Q6:How many types of sandwich panel do you have?

A: We have EPS(polystyrene)sandwich panel, rock wool sandwich panel, and PU(polyurethane)sandwich panel.

The characteristics of your sandwich panels respectively:

1.EPS(polystyrene)sandwich panel: thickness is 50mm, 75mm, 100mm. EPS volume weight is 80-200Kg/m3, water-proof.

2.Rock wool sandwich panel: thickness is 50mm, 75mm, 100mm. Rock wool volume weight is 200-400Kg /m3, fire-proof, sound-insulation, heat-preservation.

3.PU(polyurethane)sandwich panel: thickness is 50mm, 75mm, 100mm. PU volume weight is 150-300/m3 water-proof, fire-proof, heat-proof, heat-insulation, heat-preservation, sound-insulation.

Q7: How many colors do your sandwich panels have?

A: Offwhite, ivory white, blue, green and red color.